We Have Experience In Manufacturing...

Customers Served

0

+

Jobs Completed

0

+

Manufacturing Experience

0

+ Years

Cutting-Edge Solutions for Advanced Medical Manufacturing Solutions

01

Our experienced team collaborates closely with clients to design and prototype innovative medical devices. Using cutting-edge technology, we offer rapid prototyping services that quickly validate and refine designs, ensuring functionality and regulatory compliance from the start.

02

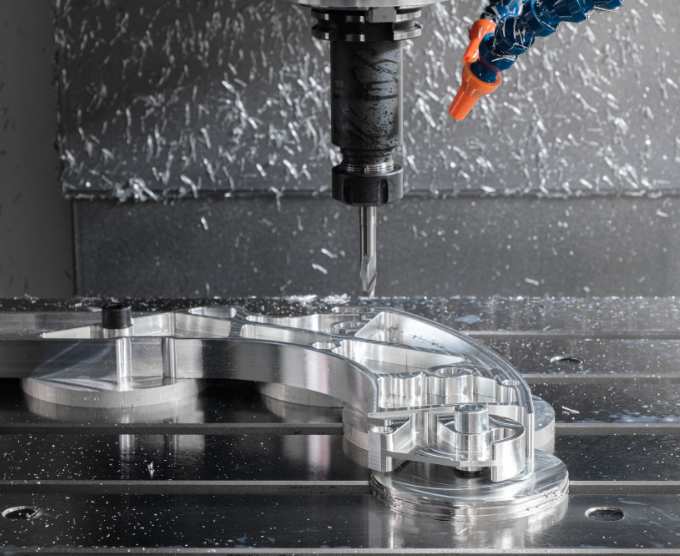

With our state-of-the-art CNC and 5-axis machining capabilities, we produce complex medical components with unmatched precision. Our advanced machinery and skilled technicians ensure that every part meets exacting specifications and tolerances, essential for critical medical applications.

03

Quality is our top priority. We adhere to stringent industry standards and certifications, including ISO 13485, to ensure that all products are safe, reliable, and effective. Our rigorous quality assurance processes include comprehensive testing and inspection at every stage of production.

Our 5-axis machining capabilities facilitate the creation of intricate medical components with exceptional precision and efficiency, adhering to the highest industry standards.

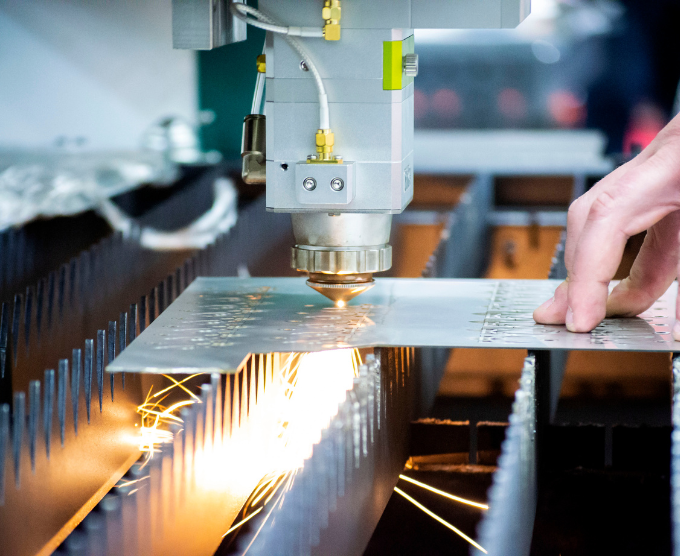

Our sheet metal fabrication capabilities deliver high-quality, precise medical components, ensuring durability and compliance with stringent healthcare standards.

Our rapid prototyping capabilities enable the swift creation of precise medical components, facilitating quick iterations and timely development of innovative medical devices.

01

Producing high-precision surgical instruments such as scalpels, forceps, clamps, and retractors.

02

Complex medical implants such as joint replacements, dental implants, and spinal implants.

03

Parts for diagnostic machines, including MRI scanners, CT scanners, and ultrasound devices.

04

Creating tiny, intricate parts for devices such as stents, pacemaker components, and drug delivery systems.

At our manufacturing facility, we utilize a range of high-quality, biocompatible materials specifically suited for medical device components. Our primary materials include:

Stainless Steel (316L):

Titanium and Titanium Alloys (e.g., Ti-6Al-4V):

Cobalt-Chrome Alloys:

Aluminum:

Our manufacturing methods allow us to precisely produce these materials into complex, high-precision components tailored to the stringent requirements of the medical industry. We ensure that all materials meet rigorous quality and safety standards to guarantee the highest performance and reliability in medical applications.

Yes, we specialize in custom manufacturing solutions tailored to specific medical device designs. Our capabilities include rapid prototyping, CNC machining, and sheet metal fabrication, allowing us to create bespoke components that meet the exact specifications of your design. This flexibility ensures that we can accommodate unique requirements and innovations in medical technology

Lead times can vary depending on the complexity and volume of the order. For custom parts, our rapid prototyping services can significantly reduce the development cycle, enabling faster iterations and quicker turnaround times. Typically, we aim to provide a detailed timeline upon reviewing the specific project requirements to ensure timely delivery.

We adhere to stringent regulatory standards, including FDA and MDR (Medical Device Regulation) guidelines. Our manufacturing processes are designed to meet these regulatory requirements, ensuring that all products are safe, effective, and compliant with international standards. We maintain comprehensive documentation and conduct regular audits to ensure ongoing compliance.

Fill out the form with your contact details to contact us.

5415 Business Pkwy Ringwood, IL 60072

Contact us today to get your project started