We Have Experience In Manufacturing...

Customers Served

0

+

Jobs Completed

0

+

Manufacturing Experience

0

+ Years

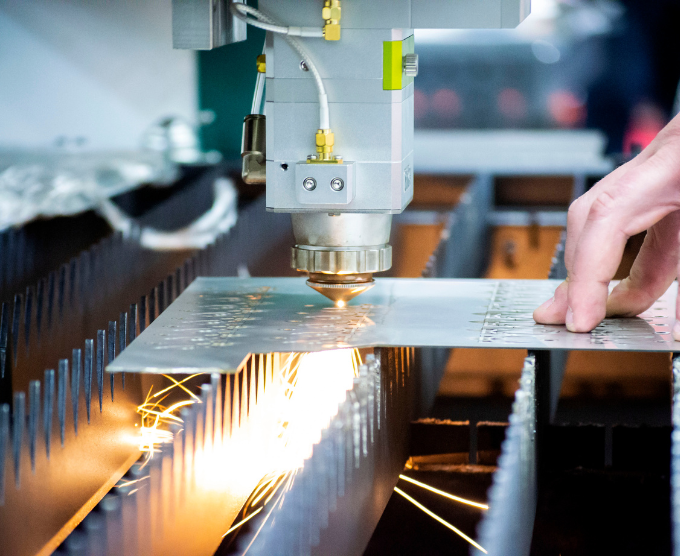

Cutting-Edge Technology for Superior Electronics Manufacturing

01

Leverage our advanced automation technologies to enhance production efficiency and reduce operational costs in your industrial processes.

02

We prioritize eco-friendly methods and materials, ensuring that our manufacturing processes minimize environmental impact while maintaining top-quality output.

03

Our expert team provides bespoke engineering solutions and rapid prototyping to meet the unique requirements of your industrial projects, ensuring precision and innovation at every step.

Our state-of-the-art 5-axis CNC machining capabilities allow us to produce highly complex and precise industrial components, ensuring unparalleled accuracy and efficiency for our clients’ most demanding applications.

Our sheet metal fabrication capabilities deliver high-quality, precise medical components, ensuring durability and compliance with stringent healthcare standards.

Our Wire EDM capabilities deliver high-precision and intricate components for the electronics industry, ensuring superior accuracy and quality for even the most complex parts.

Our advanced waterjet cutting capabilities ensure precise, clean cuts for a wide range of materials, providing high-quality components essential for the electronics industry.

01

Manufacturing high-quality printed circuit board (PCB) components, essential for the intricate and reliable operation of electronic devices.

02

Producing advanced semiconductor components, including microchips and integrated circuits, that power modern electronic devices.

03

Creating durable and precisely engineered enclosures and housings for electronic systems, ensuring protection and stability for internal components.

04

Fabricating precision connectors and interconnect systems that facilitate reliable and efficient electrical connections within electronic devices.

At our manufacturing facility, we use a range of high-quality materials tailored for the precision and reliability required in electronic components. Our primary materials include:

Stainless Steel:

Aluminum:

Copper:

Titanium:

High-Performance Alloys:

Our advanced CNC machining, sheet metal fabrication, Wire EDM, rapid prototyping, waterjet cutting, and laser engraving capabilities allow us to precisely manufacture these materials into intricate, high-quality electronic components. Each material is selected based on the specific requirements of the application, ensuring optimal performance and reliability.

Yes, we offer comprehensive custom design and prototyping services. Our team works closely with clients to develop tailored solutions, from initial concept and PCB design to rapid prototyping. This allows us to quickly identify and address any design issues before moving to mass production.

Lead times can vary depending on the complexity and volume of the order. For standard electronic components, lead times typically range from 4 to 6 weeks. For custom designs and prototyping, the timeline can be adjusted based on project requirements and client needs. We strive to provide precise timelines upon reviewing project specifics to ensure timely delivery.

We implement comprehensive traceability systems for all components used in our products. This includes maintaining detailed records of part origins, batch numbers, and quality checks throughout the production process. Our quality assurance measures involve rigorous testing and inspection at each stage to ensure every component meets our stringent quality standards.

Fill out the form with your contact details to contact us.

5415 Business Pkwy Ringwood, IL 60072

Contact us today to get your project started