EDM FAQs

Wire EDM machining offers a range of advantages that make it a standout choice for precision machining tasks, particularly for manufacturing sectors where intricate detailing and material integrity are paramount. Here’s a concise overview suitable for an EDM manufacturer’s FAQ section:

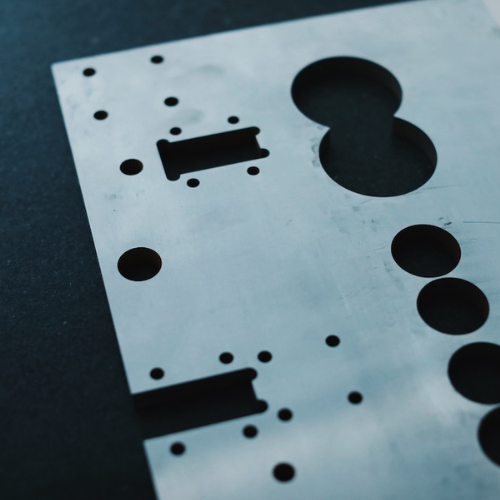

Precision and Complexity: Wire EDM allows for the cutting of complex shapes and intricate details with high precision, accommodating even the most challenging geometries that are difficult to achieve with conventional machining techniques.

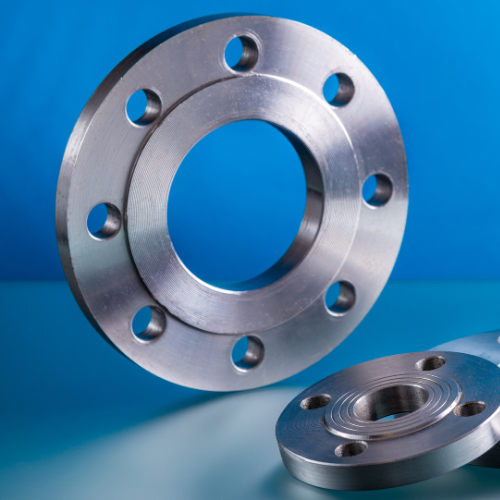

Material Versatility: This method can machine a wide array of conductive materials, regardless of hardness, without inducing stress or distortion, making it ideal for working with delicate or hard materials like hardened steel, superalloys, or titanium.

Minimal Contact: Since the cutting is done through electrical discharge without direct contact, there is minimal risk of inducing mechanical stress or deformation to the part, preserving the material integrity and dimensional accuracy.

Superior Surface Finish: Wire EDM can achieve excellent surface finishes, reducing or eliminating the need for post-machining surface treatments. This is particularly beneficial for applications requiring smooth surfaces and tight tolerances.

Cost-Effectiveness for Complex Parts: While Wire EDM might not be the fastest machining process, it offers cost benefits for producing complex parts, particularly when traditional machining methods would require multiple setups or more intricate tooling.

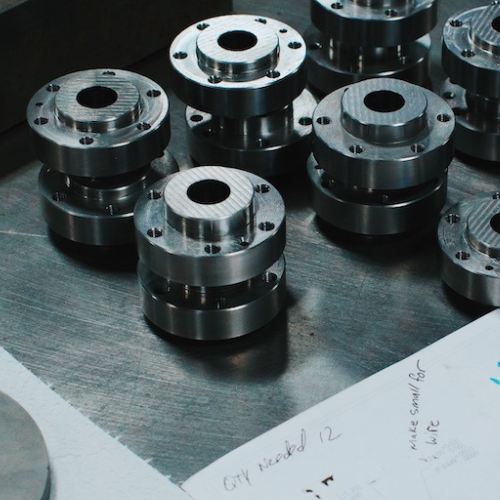

Efficient Production of Prototypes and Short Runs: The process is well-suited for prototyping and short production runs, offering flexibility and efficiency when producing or iterating on complex parts.

Incorporating these points into your FAQ section can provide potential customers with a clear understanding of Wire EDM’s unique capabilities and its suitability for various machining requirements.

Wire EDM (Electrical Discharge Machining) is renowned for its exceptional precision and accuracy, making it an ideal choice for intricate and detailed machining tasks. Our state-of-the-art Wire EDM machines boast positioning and contour accuracy within +/- 2 microns (0.00008 inches). This level of precision ensures that even the most complex parts are produced with exacting detail, meeting the highest standards of quality and consistency. Whether your project requires the machining of intricate components or the production of parts with tight tolerances, our Wire EDM services deliver unparalleled accuracy, ensuring your specifications are met with precision every time.

Comparing the costs of Wire EDM to CNC machining depends on the specifics of the job at hand. Wire EDM is generally perceived to be more expensive due to its slower cutting speed; however, it excels in complexity and precision, often making it a more cost-effective solution for intricate or hardened materials that are challenging for CNC machining.

For simpler, high-volume parts, CNC machining might be more economical due to its faster removal rates and lower operating costs. However, for complex, precision parts or materials that are difficult to machine using conventional methods, Wire EDM can provide a superior finish with less post-processing, potentially reducing overall costs.

Ultimately, the choice between Wire EDM and CNC machining should be based on the specific requirements of the part, including its material, geometry, and tolerance specifications. Consulting with a machining expert can provide a clearer cost comparison based on your project’s unique needs.