We Have Experience In Manufacturing...

Customers Served

0

+

Jobs Completed

0

+

Manufacturing Experience

0

+ Years

Innovative Technologies for Advanced Automotive Manufacturing

01

Our advanced manufacturing processes ensure precise and accurate production of automotive components, meeting the industry's exacting standards.

02

Utilizing state-of-the-art technology, we deliver cutting-edge solutions that enhance vehicle performance, safety, and efficiency.

03

Our manufacturing capabilities are designed to scale and adapt to varying production volumes, accommodating both small and large projects with consistent quality and reliability.

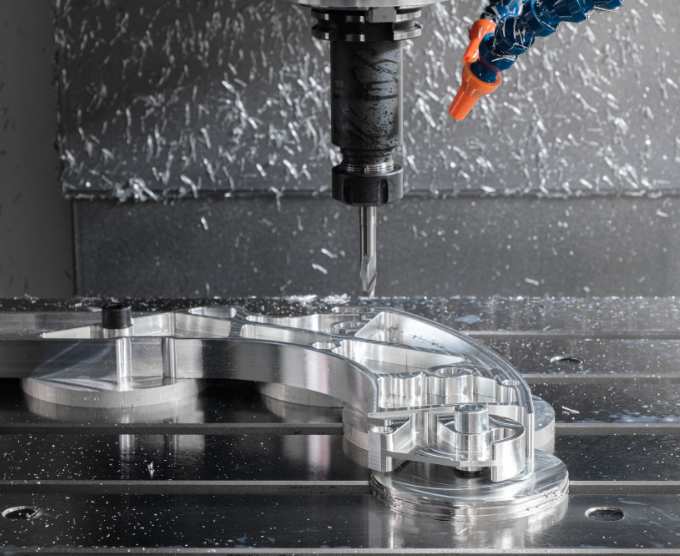

Our 5-axis machining capabilities enable the production of complex automotive components with unmatched precision and efficiency, meeting the industry’s highest standards.

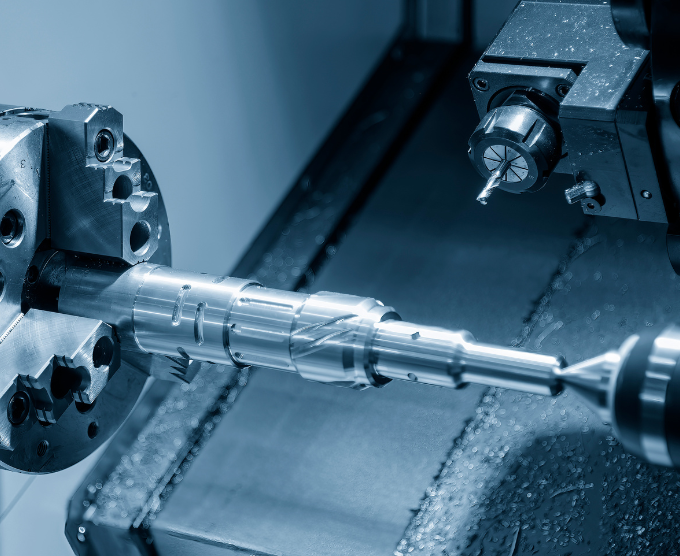

Our CNC turning expertise delivers intricately crafted, high-tolerance automotive parts, ensuring optimal performance and reliability.

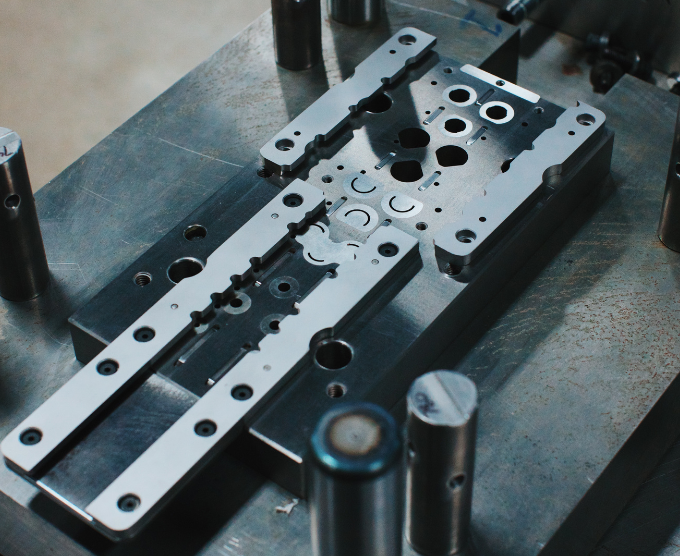

Our tool and die services provide precision-engineered molds and dies, ensuring high-quality and reliable automotive component production.

01

Manufacturing critical engine parts such as pistons, crankshafts, camshafts, and cylinder heads.

02

Producing gears, shafts, and housing for automatic and manual transmission systems.

03

Fabricating structural components such as frames, control arms, and suspension links.

04

Stamping and forming metal sheets into body panels, doors, hoods, and roof sections.

We use a variety of high-quality materials tailored to the specific requirements of automotive applications, including various grades of steel, aluminum, plastics, and advanced composites. These materials are selected for their strength, durability, and performance characteristics to ensure optimal functionality and longevity of our parts.

Yes, we offer comprehensive custom design and engineering services. Our experienced team collaborates closely with clients to develop tailored solutions that meet their specific needs. From initial concept and design to final production, we ensure each part is optimized for performance, manufacturability, and cost-effectiveness.

Our production capacity is designed to handle both small and large-scale projects efficiently. Lead times vary depending on the complexity and volume of the parts, but we are committed to delivering high-quality components within the agreed-upon timeframe. For specific project details, we provide customized timelines to meet your scheduling needs.

Yes, we offer comprehensive prototyping and testing services. Our rapid prototyping capabilities allow us to produce accurate models and prototypes quickly, facilitating early design validation and iteration. Additionally, we conduct thorough testing to ensure that prototypes meet all performance and quality standards before moving on to full-scale production.

Fill out the form with your contact details to contact us.

5415 Business Pkwy Ringwood, IL 60072

Contact us today to get your project started