We Have Experience In Manufacturing...

Customers Served

0

+

Jobs Completed

0

+

Manufacturing Experience

0

+ Years

Advanced Manufacturing Capabilities for Aerospace Excellence

01

Our advanced production capabilities blend traditional methods with state-of-the-art advanced manufacturing, ensuring high-quality results for every project.

02

We strictly follow industry-leading quality management standards, guaranteeing that every product meets rigorous aerospace requirements.

03

Our expertise in innovative part design and lightweighting techniques allows us to create efficient, high-performance aerospace components.

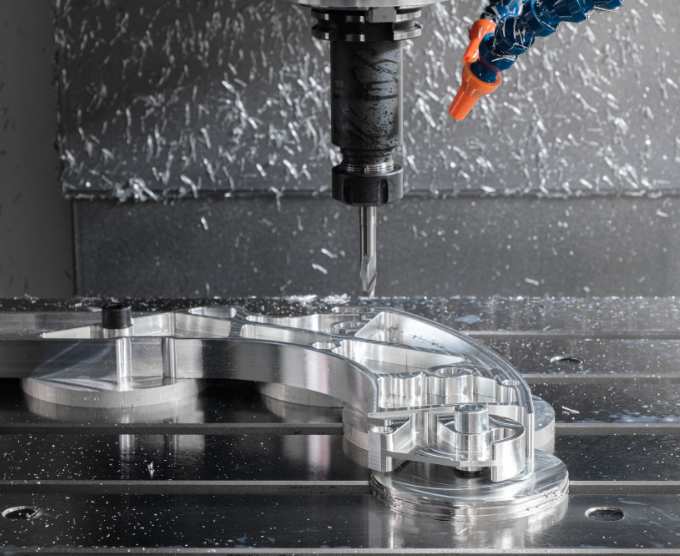

Our CNC machining capabilities ensure precise, high-quality production of complex aerospace components, meeting the industry’s stringent performance and reliability standards.

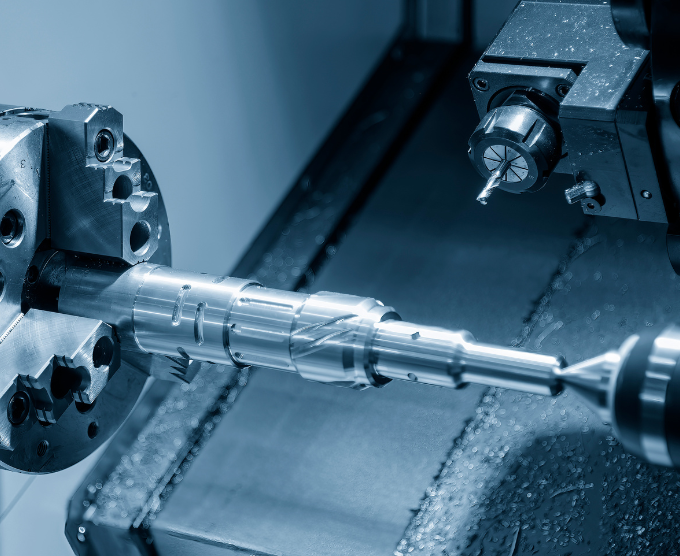

Our CNC turning capabilities deliver precision-crafted, high-quality cylindrical components, tailored to meet the exacting standards of the aerospace industry.

Our rapid prototyping services provide fast, accurate models and prototypes, enabling quick iterations and efficient development of aerospace components.

01

Manufacturing critical structural parts such as fuselage sections, wings, and landing gear assemblies.

02

Producing high-performance turbine blades, compressor discs, and other essential engine components.

03

Crafting durable and lightweight housings for avionics systems, including navigation, communication, and control equipment.

04

Fabricating precision parts for satellites, including frames, antennas, and propulsion system components.

We use a variety of high-performance materials to manufacture aerospace parts, including aluminum alloys, titanium, stainless steel, and advanced composites. These materials are chosen for their strength, durability, and ability to withstand the extreme conditions of aerospace applications.

Yes, we offer comprehensive custom design and engineering services. Our experienced team works closely with clients to develop tailored solutions that meet specific requirements. From initial concept and design to final production, we ensure that each part is optimized for performance and manufacturability.

Our production capacity is designed to handle both small and large-scale projects efficiently. Lead times vary depending on the complexity and quantity of the parts, but we are committed to delivering high-quality components within the agreed-upon timeframe. For specific project details, we provide customized timelines to meet your scheduling needs.

Yes, we offer rapid prototyping and testing services to help clients quickly validate their designs. Our rapid prototyping capabilities allow us to produce accurate models and prototypes in a short amount of time. Additionally, we conduct thorough testing to ensure that prototypes meet all performance and quality standards before moving on to full-scale production.

Fill out the form with your contact details to contact us.

5415 Business Pkwy Ringwood, IL 60072

Contact us today to get your project started