RWD Does Engineering & Design

RWD has many different types of mechanical engineering design services that could help you on your next project. We can do everything from creating a complete mechanical design of your new project to modifying or correcting a current design.

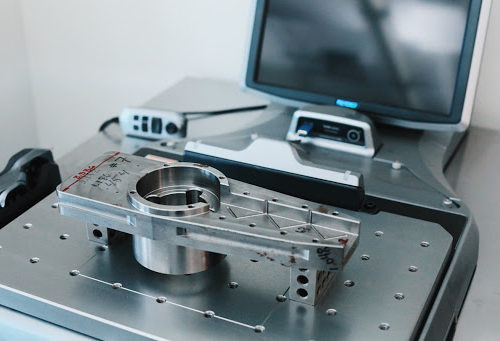

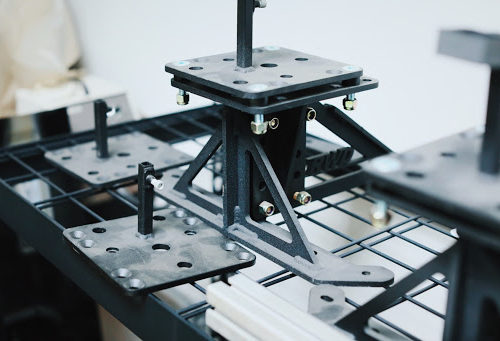

We have state-of-the-art 3D CAD systems for mechanical design, as well as a variety of tools / equipment for mechanical analysis and testing. Our combination of experienced engineers and design tools allows Indesign to deliver you a mechanical design optimized for functionality and manufacturability.