Precision manufacturing is critical to the manufacturing sector, ensuring high-quality products and efficient processes. In today’s competitive market, businesses need precise and reliable manufacturing solutions to stay ahead. Precision manufacturing involves using advanced technologies and specialized techniques to create finished products with exact specifications. From CNC machining to waterjet cutting, precision manufacturing encompasses various methods to achieve precision and accuracy.

In this blog, we will explore the world of precision manufacturing and how it has evolved over the years. We will explore the core technologies behind precision manufacturing, such as CNC machining, waterjet cutting, and laser cutting. Additionally, we will discuss specialized services offered by precision manufacturing companies, including prototyping and electrical discharge machining. Furthermore, we will highlight the business benefits of partnering with a precision manufacturing company and share success stories that demonstrate the difference precision manufacturing can make.

Whether you are in the aerospace, automotive, electronics, or any other industry, precision manufacturing solutions can cater to your specific needs and requirements. By leveraging the expertise and capabilities of precision manufacturing companies, you can optimize your manufacturing processes, enhance product quality, and achieve greater efficiency. Join us as we explore the world of precision manufacturing and discover how it can revolutionize your business.

Exploring the World of Precision Manufacturing

Precision manufacturing is crucial to the manufacturing process, ensuring the final product meets the exact specifications and requirements. It involves a series of steps, from raw material selection to the assembly line, to create finished products with exceptional precision and accuracy.

Thanks to the evolution of technology, the manufacturing sector has witnessed significant advancements over the years. From the Industrial Revolution to the introduction of advanced manufacturing technologies, the sector has transformed the way products are made. Advanced technologies, such as robotics, automation, and artificial intelligence, have revolutionized manufacturing, enabling faster production, improved quality control, and reduced costs.

Precision manufacturing is essential in various industries, including aerospace, automotive, electronics, and more. Each industry has unique requirements, and precision manufacturing ensures that these requirements are met. Precision is paramount when creating intricate components for aeronautical applications or manufacturing high-quality electronic equipment.

One key aspect of precision manufacturing is the use of lean manufacturing principles. Lean manufacturing focuses on eliminating waste and optimizing production processes to maximize efficiency. By implementing lean manufacturing techniques, manufacturers can reduce costs, improve quality control, and streamline operations.

Overall, precision manufacturing plays a vital role in the manufacturing sector by ensuring the production of high-quality products with the utmost precision and accuracy. It is a combination of advanced technologies, efficient manufacturing processes, and a commitment to quality control that makes precision manufacturing an essential part of today’s industry.

The Evolution and Impact of Advanced Manufacturing Technologies

The manufacturing sector has experienced a significant evolution over the years, driven by the introduction of advanced manufacturing technologies. From the industrial revolution to the digital age, these technologies have revolutionized the way products are manufactured.

The industrial revolution marked a turning point in manufacturing, with the introduction of steam power and mechanization. This allowed for mass production on a larger scale, leading to the rise of factories and assembly lines. The advent of electricity further enhanced manufacturing capabilities, enabling faster and more efficient production processes.

In recent years, advanced technologies such as robotics, automation, and artificial intelligence have transformed the manufacturing sector. These technologies have enabled lean manufacturing, where waste is minimized and efficiency is maximized. Robotics and automation have taken over repetitive and labor-intensive tasks, allowing human workers to focus on more complex and creative aspects of manufacturing.

In recent years, advanced technologies such as robotics, automation, and artificial intelligence have transformed the manufacturing sector. These technologies have enabled lean manufacturing, where waste is minimized and efficiency is maximized. Robotics and automation have taken over repetitive and labor-intensive tasks, allowing human workers to focus on more complex and creative aspects of manufacturing.

The impact of advanced manufacturing technologies can be seen in various industries. For example, in the automotive industry, robots are used for assembly line processes, increasing efficiency and precision. In the electronics industry, automated machines are used to manufacture intricate component parts for electronic devices.

Overall, advanced manufacturing technologies have revolutionized the manufacturing sector, making it more efficient, precise, and cost-effective. These technologies have played a significant role in the evolution of precision manufacturing and continue to shape the industry’s future.

Why Precision Matters in Today’s Industry

Precision is of utmost importance in today’s manufacturing industry, as it ensures the quality and reliability of the final product. In a highly competitive market, manufacturers need to deliver products that meet the highest standards of precision to stay ahead of the competition.

Quality control is a crucial aspect of precision manufacturing. By implementing stringent quality control measures, manufacturers can ensure that every product that leaves the assembly line meets the specified requirements. This helps build trust with customers and enhances the reputation of the manufacturing business.

The type of manufacturing also plays a role in the importance of precision. In industries such as aerospace and automotive, where safety and reliability are paramount, precision manufacturing is essential. Even a slight deviation from the specified measurements can have significant consequences in these industries. On the other hand, precision is equally important in industries such as electronics, where intricate components need to fit together perfectly for the final product to function correctly.

Precision manufacturing also enables manufacturers to optimize their production processes. By minimizing waste and ensuring accurate measurements, manufacturers can reduce costs and improve efficiency. This leads to increased productivity and better utilization of resources.

In conclusion, precision matters in today’s industry because it ensures the quality, reliability, and efficiency of the manufacturing process. From quality control to optimizing production processes, precision manufacturing plays a vital role in meeting the demands of the modern market.

The Core Technologies Behind Precision Manufacturing

Precision manufacturing relies on core technologies such as CNC machining, waterjet cutting, and laser cutting. These advanced techniques enable the creation of intricate components with high accuracy and repeatability. CNC machining is pivotal for precise shaping, while waterjet cutting offers versatility across various materials. Laser cutting and engraving ensure detailed and refined outcomes. These technologies form the backbone of precision manufacturing, ensuring the production of top-quality components for a wide range of industries.

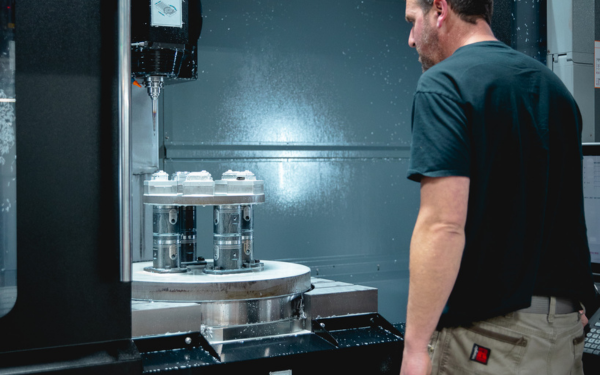

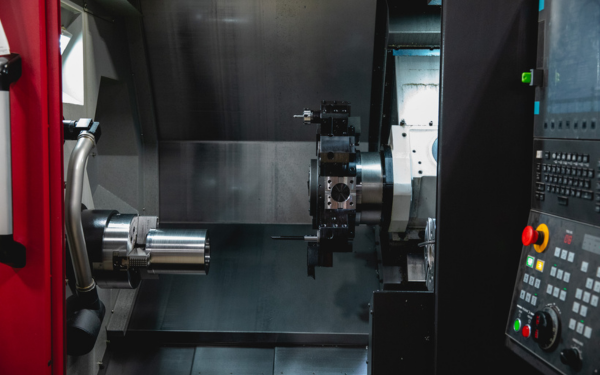

CNC Machining: The Backbone of Precision

CNC machining stands as the backbone of precision manufacturing, vital for crafting intricate components with utmost accuracy. By utilizing computer-controlled systems, CNC machining ensures consistent quality in the production process. This advanced method plays a key role in streamlining manufacturing operations, offering efficient and precise solutions for various industry needs. CNC machining optimizes production workflows, enhancing overall productivity while maintaining the highest standards of precision and quality. Its versatility and reliability make CNC machining indispensable in modern manufacturing environments.

Waterjet Cutting: Versatility in Manufacturing

Waterjet cutting is a versatile manufacturing technique that utilizes high-pressure streams of water to cut a wide range of materials with precision. This method is highly adaptable, allowing for intricate designs and shapes to be produced efficiently. Waterjet cutting is ideal for industries requiring intricate cuts, such as aerospace and automotive. Its ability to cut materials without heat-affected zones makes it a preferred choice for projects where material integrity is crucial. Waterjet cutting stands out for its flexibility and accuracy in addressing diverse manufacturing needs.

Laser Cutting and Engraving: Detail-Oriented Solutions

Laser cutting and engraving offer detail-oriented solutions, ensuring precise and intricate designs for various manufacturing needs. This advanced manufacturing technology uses a highly focused laser beam to cut through materials with exceptional accuracy, creating finely detailed patterns and engraving with utmost precision. From custom signage to delicate components, laser cutting and engraving provide a high level of customization and intricacy, making them ideal for industries where precision and attention to detail are paramount.

Beyond the Basics: Specialized Services in Precision Manufacturing

Prototyping services offered in precision manufacturing facilitate the transformation of concepts into tangible products. Electrical Discharge Machining (EDM) is adept at handling intricate geometries with precision. Additionally, streamlined engineering and design services ensure projects are seamlessly executed from inception to finalization. These specialized services elevate the manufacturing process by integrating advanced techniques to meet client specifications effectively.

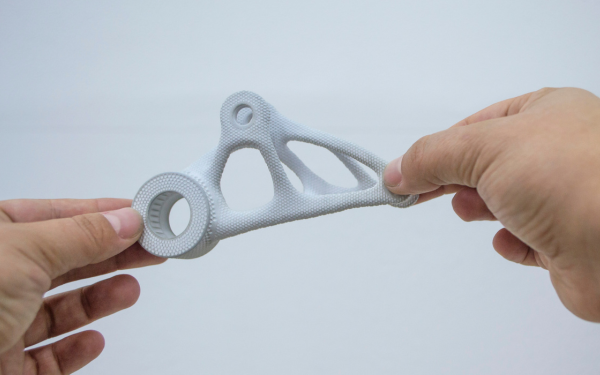

Prototyping: Turning Ideas into Reality

Prototyping is a crucial step in turning conceptual ideas into tangible products. By creating initial models to test and refine designs, manufacturers can validate concepts before investing in mass production. This process allows for adjustments based on feedback, reducing risks and ensuring a more efficient manufacturing process. Effective prototyping enhances product quality, accelerates time-to-market, and ultimately leads to successful manufacturing outcomes. Leveraging prototyping in the manufacturing sector enables companies to innovate rapidly, address customer needs efficiently, and stay ahead in competitive markets.

Electrical Discharge Machining (EDM): Tackling Complex Geometries

Electrical Discharge Machining (EDM) is a specialized precision manufacturing process used to tackle complex geometries that are difficult to achieve with conventional machining methods. It involves the use of electrical discharges to remove material from a workpiece, resulting in intricate shapes and intricate features.

EDM is particularly useful when working with hard or exotic materials that are challenging to machine using traditional methods. It is commonly used in the aerospace, automotive, and medical manufacturing industries, where precision and complexity are essential for successful manufacturing.

By utilizing EDM, precision manufacturing companies can produce intricate components and parts from raw materials with high accuracy. The EDM process allows for precise control over the cutting path, enabling manufacturers to create complex shapes and features that would be otherwise difficult or impossible to achieve.

Comprehensive Engineering and Design Services: From Concept to Completion

Precision manufacturing companies offer comprehensive engineering and design services that encompass the entire product development process, from concept to completion. These services leverage the expertise of engineers and designers to bring innovative ideas to life and ensure seamless integration into the manufacturing process.

Engineering and Design Services

– Concept development and feasibility studies

– Product design and 3D modeling

– Design for manufacturing and assembly

– Material selection and sourcing

– Supply chain management

– Prototype production and testing

– Process optimization and efficiency improvement

– Quality control and assurance

– Continuous improvement and product lifecycle management

By providing end-to-end engineering and design services, precision manufacturing companies can streamline the product development process, reduce time to market, and improve overall product quality. From initial concept development to final production, these services ensure that every aspect of the product’s design and manufacturing is optimized for efficiency and performance.

Maximizing Efficiency with Rapid Waterjet Designs

Rapid Waterjet Designs is a leading precision manufacturing company that specializes in maximizing efficiency through their advanced waterjet cutting solutions. With their state-of-the-art facilities and skilled team, they offer a wide range of services to meet the demands of various industries.

One of the key advantages of working with Rapid Waterjet Designs is their ability to help businesses reduce waste and optimize their inventory. By providing waterjet cutting services, they can efficiently cut through different materials, allowing businesses to utilize their stock of unwanted parts and transform them into valuable components. This not only helps businesses save costs but also minimizes their environmental impact.

Another significant benefit of Rapid Waterjet Designs is their ability to meet market demand effectively. With their advanced waterjet cutting technology and skilled operators, they can quickly produce high-quality parts in large volumes. This enables businesses to respond to market demands promptly and efficiently, ensuring that they stay competitive in their respective industries.

Tailored Solutions for Diverse Client Needs

Rapid Waterjet Designs is known for providing tailored solutions to meet the diverse needs of their clients. Whether it’s customizing parts according to specific customer orders or finding innovative solutions to manufacturing challenges, they strive to deliver the highest level of quality and precision.

Their expertise in precision manufacturing goes beyond traditional processes, allowing them to tackle complex projects and deliver exceptional results. With their state-of-the-art equipment and experienced team, they can handle projects of varying scales and complexities, ensuring that every client receives the utmost attention and satisfaction.

One of their notable success stories includes their collaboration with Toyota Motor Corporation. Rapid Waterjet Designs worked closely with Toyota to provide precision components for their manufacturing processes. By leveraging their advanced waterjet cutting technology and expertise, they were able to meet Toyota’s strict quality standards and deliver components that met their exact specifications.

Commitment to Innovation and Quality

Rapid Waterjet Designs is committed to innovation and quality in every aspect of their precision manufacturing solutions. They strive to deliver the highest quality products that meet and exceed their clients’ expectations.

Innovation plays a significant role in their operations, as they continuously invest in the latest technologies and techniques to improve their manufacturing processes. By staying at the forefront of industry advancements, they can offer cutting-edge solutions that maximize efficiency and precision.

Quality control is also a top priority for Rapid Waterjet Designs. They have stringent quality control measures in place to ensure that every product they deliver meets the highest standards. From material selection to final inspection, they pay meticulous attention to detail to guarantee the quality and reliability of their goods.

By maintaining a strong focus on innovation and quality, Rapid Waterjet Designs has earned a trusted reputation in the precision manufacturing industry. Their commitment to delivering exceptional products and services has allowed them to build long-lasting relationships with their clients and establish themselves as a leader in the market.

The Business Benefits of Partnering with Rapid Waterjet Designs

Partnering with Rapid Waterjet Designs offers numerous business benefits, including cost-effective solutions for competitive markets and enhanced productivity through advanced technologies.

Cost-Effective Solutions for Competitive Markets

Rapid Waterjet Designs understands the challenges of operating in competitive markets. They provide cost-effective solutions that help businesses stay competitive without compromising on quality. By leveraging their advanced waterjet cutting technology and efficient manufacturing processes, they can offer competitive pricing and quick turnaround times.

Their expertise in various manufacturing types, such as job shop manufacturing, allows them to tailor their solutions to meet the unique needs of each client. Whether it’s a small batch or large-scale production, Rapid Waterjet Designs can accommodate different project sizes and deliver cost-effective solutions that maximize efficiency and profitability.

Enhancing Productivity Through Advanced Technologies

Rapid Waterjet Designs understands the importance of enhancing productivity to stay ahead in today’s fast-paced manufacturing industry. By incorporating advanced technologies into their processes, they can minimize reliance on human labor, reduce production time, and produce goods at a higher speed without compromising quality.

Their advanced waterjet cutting technology allows for precise and efficient material cutting, resulting in faster production cycles and lower costs. This enables Rapid Waterjet Designs to offer competitive pricing while maintaining exceptional quality standards.

Additionally, their focus on advanced technologies reduces the need for handmade goods, which often come at a higher price and have longer production lead times. By leveraging their state-of-the-art equipment and expertise, Rapid Waterjet Designs can deliver high-quality products efficiently, helping businesses save time and resources.

Success Stories: How Precision Manufacturing Made a Difference

Precision manufacturing has made a significant difference in various industries and has contributed to economic growth and development. Several success stories highlight the impact of precision manufacturing over a given period of time.

One such success story is the transformation of the manufacturing sector, which has benefited the general public by providing access to high-quality products at affordable prices. Precision manufacturing enables economies of scale, allowing businesses to produce goods in large quantities, resulting in lower production costs. This, in turn, benefits consumers by making products more affordable and accessible.

Precision manufacturing has also played a crucial role in supporting industries that rely on high-quality and precision components, such as aerospace, automotive, and electronics. The ability to produce intricate and precise parts has revolutionized these industries, enabling advancements in technology and improving overall product performance.

Moreover, precision manufacturing has contributed to job creation and economic stability. By embracing advanced technologies and efficient manufacturing processes, businesses can enhance productivity and competitiveness, leading to growth and expansion. This, in turn, creates employment opportunities and drives economic growth at both the local and national levels.

Case Study Highlights: Overcoming Industry Challenges

A case study conducted by the Conference Board in the early 20th century highlights the transformative impact of precision manufacturing in overcoming industry challenges. The study focused on a manufacturing company that faced various obstacles in their production processes but successfully overcame them through the adoption of precision manufacturing practices.

Bullet points:

- The company leveraged precision manufacturing technologies to improve the quality and precision of their core assets.

- By implementing lean manufacturing principles, they were able to optimize their production processes, reduce waste, and enhance overall efficiency.

- The adoption of precision manufacturing practices allowed the company to achieve significant cost savings and increase their competitive advantage.

This case study showcases the positive impact of precision manufacturing in tackling industry challenges and driving success. It demonstrates how embracing advanced technologies and optimizing manufacturing processes can lead to improved productivity, higher quality products, and increased profitability.

Testimonials: What Our Clients Say About Us

Rapid Waterjet Designs has received praise from their clients for their exceptional precision manufacturing solutions. Here are some testimonials from satisfied customers:

Testimonials:

- “Rapid Waterjet Designs has been our go-to partner for precision manufacturing. Their expertise in chemical processing and assembly line manufacturing has helped us achieve high-quality products with efficiency.” – ABC Manufacturing Company

- “We have been working with Rapid Waterjet Designs for several years, and they have consistently delivered excellent results. Their precision manufacturing capabilities have significantly improved our assembly line processes.” – XYZ Electronics Corporation

- “Rapid Waterjet Designs’ attention to detail and commitment to quality have made them a trusted partner in our manufacturing operations. Their assembly line manufacturing solutions have greatly enhanced our productivity and product consistency.” – DEF Automotive Industries

These testimonials highlight the satisfaction and trust that clients have in Rapid Waterjet Designs’ precision manufacturing services. Their ability to meet and exceed client expectations has solidified their reputation as a reliable and innovative partner in the industry.

Start Your Project with Rapid Waterjet Design!

If you’re looking for precision manufacturing solutions to bring your ideas to life or optimize your current manufacturing processes, Rapid Waterjet Design is the perfect partner for your project. With their advanced waterjet cutting technology and expertise, they can deliver high-quality results that meet your exact specifications.

Whether you need precise components for an actual product or want to streamline your industrial process, Rapid Waterjet Design has the knowledge and capabilities to provide tailored solutions. They understand the importance of using the right manufacturing methods to achieve optimal results, and they are committed to delivering excellence in every aspect of their work.

By partnering with Rapid Waterjet Design, you can benefit from their state-of-the-art facilities, skilled team, and commitment to innovation and quality. They will work closely with you throughout the project, ensuring that your specific requirements are met and that the final product exceeds your expectations.

Don’t settle for less when it comes to precision manufacturing. Start your project with Rapid Waterjet Design and experience the difference that their expertise and advanced technology can make. Contact them today to discuss your project and discover how their precision manufacturing solutions can help you achieve your goals.

Frequently Asked Questions

What Makes Rapid Waterjet Design Different?

Rapid Waterjet Design stands out from the competition due to their unique approach to precision manufacturing. Their focus on advanced technologies, efficient production processes, and dedication to quality sets them apart in the industry.

How Does Rapid Waterjet Designs Ensure Quality?

Rapid Waterjet Designs ensures quality through rigorous quality control measures at every stage of the manufacturing process. They adhere to lean manufacturing principles and utilize advanced technologies to achieve consistent and high-quality manufacturing output.

Can Custom Parts Be Produced at a Competitive Price?

Rapid Waterjet Designs offers custom part production at a competitive price. Through economies of scale, efficient processes, and the ability to meet market demand, they can provide cost-effective solutions tailored to customer orders without compromising on quality. Their expertise in precision manufacturing allows them to deliver exceptional results while maintaining competitive pricing.