Low-Volume Prototyping: Industrial Applications

Low-volume prototyping is a crucial process in the field of manufacturing, with various applications in different industries. It plays a significant role in the development and production of prototype parts, helping companies test and validate their designs before moving on to mass production. In this blog, we will explore the concept of low-volume prototyping, its importance in industrial applications, the techniques employed, and the strategies for effective implementation. We will also discuss real-life case studies, the challenges faced, and how low-volume prototyping has revolutionized industries. So, let’s dive in and understand the world of low-volume prototyping and its industrial applications.

Exploring Low-Volume Prototyping

Low-volume prototyping, as the name suggests, focuses on the production of limited quantities of parts. It serves as the starting point for the production process, allowing manufacturers to validate the design and functionality of the product. Unlike mass production, low-volume prototyping involves the production of smaller batches of parts, ensuring high strength and durability. It is a critical step in the development of new products, providing companies with the opportunity to test their ideas and make design changes based on customer feedback.

Defining Low-Volume Prototyping

Low-volume prototyping, also known as low volume manufacturing, is the process of producing limited quantities of parts for prototype development. It enables manufacturers to create a small batch of parts to test the design, functionality, and performance of a product. This process is particularly useful for new product development, allowing companies to assess the feasibility of their design concepts and make any necessary adjustments before committing to full-scale production.

Low-volume prototyping caters to the production of limited quantities of parts, typically in batches of tens, hundreds, or thousands. By producing smaller quantities, manufacturers can evaluate the quality, strength, and durability of the parts without incurring the high costs associated with mass production.

The process of low-volume prototyping is well-suited for customization and personalization of parts, catering to the specific needs of customers. It allows manufacturers to quickly iterate and make design changes, ensuring the final product meets the desired specifications. Additionally, limited quantities of parts can be produced using various manufacturing processes, such as CNC machining, injection molding, additive manufacturing, and more.

Differentiating Between Prototyping and Mass Production

It is essential to differentiate between prototyping and mass production to understand the significance of low-volume prototyping. Prototyping focuses on the rapid production of prototype parts for design validation and testing purposes. It allows companies to test the functionality, durability, and performance of a product before moving on to mass production.

On the other hand, mass production involves the large-scale production of a product using standardized production processes. Mass production aims to manufacture products in high volumes to meet market demands.

While prototyping focuses on limited quantities of parts, mass production caters to high-volume production. The production processes involved in prototyping and mass production may also differ. Prototyping processes, such as CNC machining, rapid prototyping, and additive manufacturing, are used to quickly produce prototype parts for design verification. Mass production processes, such as injection molding, sheet metal fabrication, and plastic injection molding, are optimized for high-volume production with efficient manufacturing processes.

By differentiating prototyping and mass production, it becomes apparent why low-volume prototyping plays a crucial role in the development of new products before initiating mass production. It allows companies to identify design flaws, test different production processes, and make design changes without the high costs associated with mass production.

The Crucial Role of Low-Volume Prototyping

Low-volume prototyping plays a crucial role in industrial applications by providing companies with an effective tool for product development and design validation. It serves as a stepping stone, allowing manufacturers to test their ideas, make design changes, and mitigate risks before investing in mass production. By utilizing low-volume prototyping, companies can reduce time-to-market, optimize production processes, and ensure high quality. Let’s explore the importance of low-volume prototyping in pilot projects and limited production runs.

Importance in Pilot Projects

Pilot projects are an essential stage in product development, where companies test the feasibility of a product or concept before investing in full-scale production. Low-volume prototyping plays a crucial role in pilot projects, enabling manufacturers to assess the performance, functionality, and durability of the product in the real-world environment.

By leveraging low-volume prototyping, companies can gather valuable test results, validate design changes, and address any potential design flaws. This iterative process allows for rapid development and refinement of the product, leading to a higher chance of success in the market. Furthermore, low-volume prototyping allows for customization and adjustments based on customer feedback, ensuring the final product meets the specific needs of the end-user.

Significance in Limited Production Runs

In addition to pilot projects, low-volume prototyping holds great significance in limited production runs. Companies often require smaller quantities of parts for various purposes, such as customization, limited edition products, or fulfilling niche market demands. Low-volume prototyping allows manufacturers to produce these smaller batches of parts efficiently, ensuring high quality and quick turnaround times.

By utilizing low-volume manufacturing techniques, companies can meet the demand for limited production runs without committing to the high costs and complex tooling processes associated with mass production. This flexibility benefits industries such as automotive, aerospace, medical devices, and consumer electronics, where customization and exclusivity are highly valued.

Techniques Employed in Low-Volume Prototyping

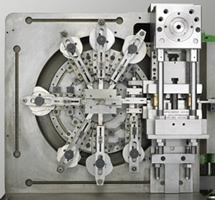

To achieve efficient low-volume prototyping, different manufacturing techniques are employed depending on the requirements of the product. CNC machining, additive manufacturing, injection molding, and vacuum casting are some of the commonly used techniques in low-volume prototyping. These techniques offer different advantages in terms of production speed, cost, complexity, and material options. Let’s delve into the details of two widely used techniques: CNC machining and additive manufacturing/3D printing.

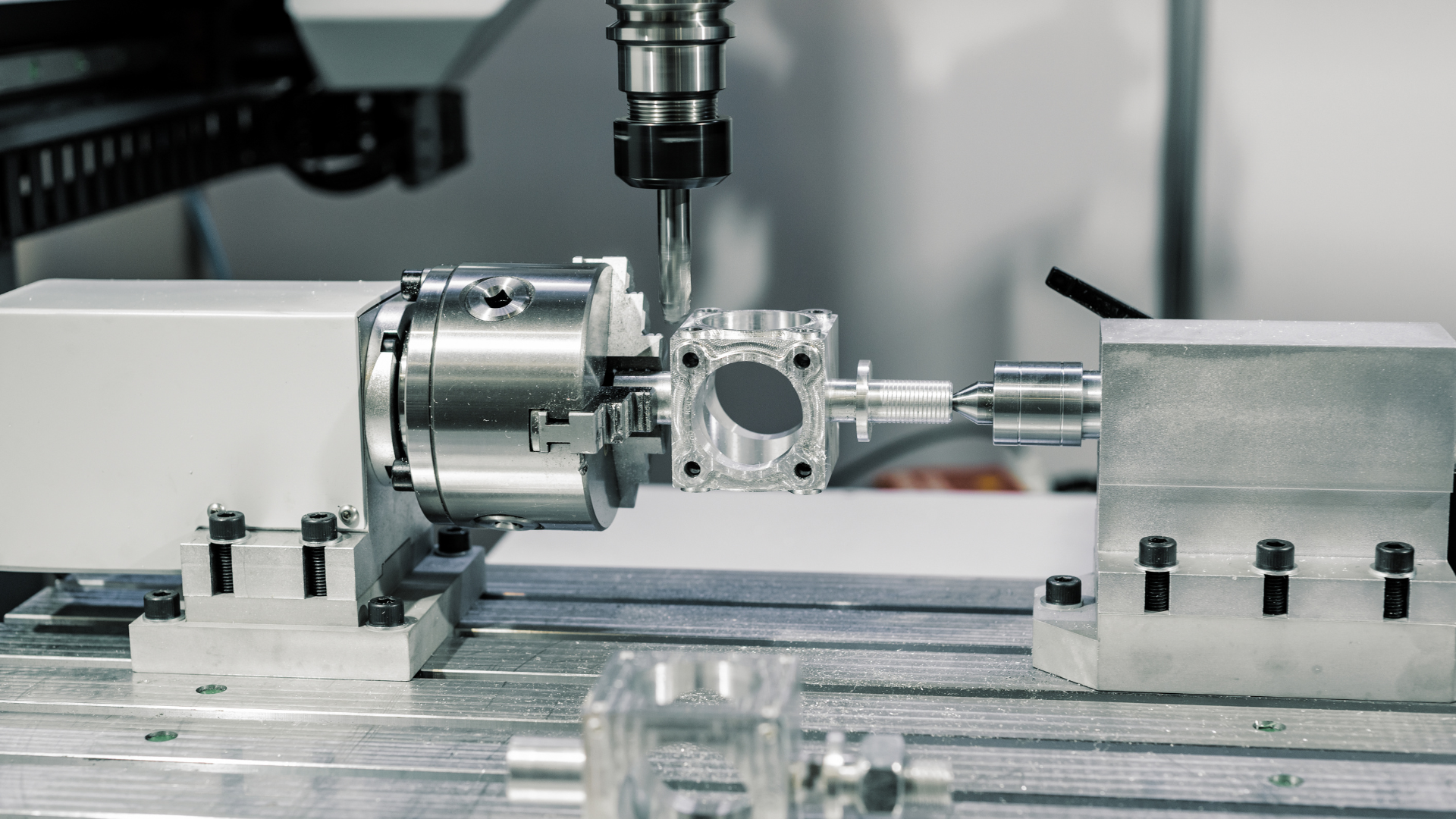

CNC Machining in Prototyping

CNC machining is a subtractive manufacturing process that utilizes computer-controlled machines to remove material from a solid block, creating the desired shape of the part. It is widely used in low-volume prototyping due to its high precision, excellent surface finish, and ability to work with a wide variety of materials.

Some key points about CNC machining in prototyping include:

- CNC machining offers tight tolerances, ensuring the accuracy and quality of the prototype parts.

- It allows for the production of parts with complex geometries, intricate features, and tight tolerances.

- CNC machining is suitable for producing both plastic and metal parts, offering flexibility in material selection.

- It provides quick turnaround times, enabling rapid prototyping for design verification.

- CNC prototyping services provide cost-effective solutions for low-volume production, reducing overall production costs.

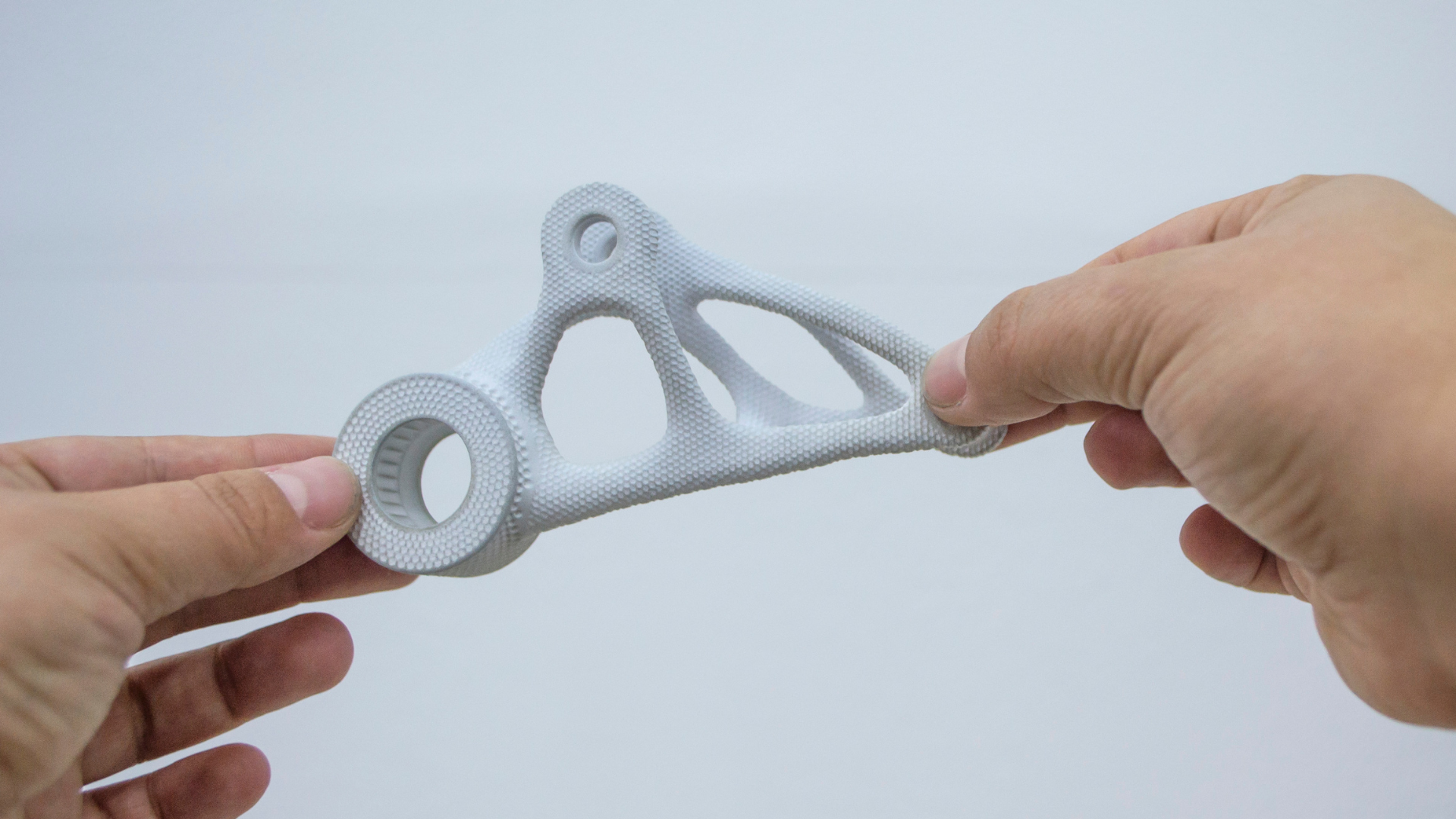

The Role of Additive Manufacturing/3D Printing

Additive manufacturing, commonly known as 3D printing, is a process that builds parts layer by layer from a digital design file. It has revolutionized low-volume prototyping and rapid prototyping, offering significant advantages over traditional manufacturing processes.

Key points about the role of additive manufacturing/3D printing in low-volume prototyping include:

- Additive manufacturing enables the quick production of prototype parts, eliminating the need for tooling or molds.

- It allows for the production of complex geometries and intricate designs, which may not be achievable with traditional manufacturing processes.

- 3D printing offers the flexibility to produce parts in a wide range of materials, including plastics, metals, ceramics, and thermoplastics.

- Rapid prototyping services leveraging additive manufacturing provide shorter lead times, allowing for faster design iterations and validation.

- The cost-effectiveness of additive manufacturing makes it an ideal choice for low-volume prototyping, reducing production costs compared to traditional manufacturing methods.

Industrial Applications of Low-Volume Prototyping

Low-volume prototyping finds applications in various industrial sectors, catering to the unique requirements of different products. From rapid prototyping to short-run production, the versatility of low-volume prototyping makes it an indispensable tool for product development. Let’s explore the industrial applications where low-volume prototyping plays a crucial role.

Application in Rapid Prototyping

Rapid prototyping is a vital part of the product development process, where quick turnaround times and iterative design changes are of utmost importance. Low-volume prototyping techniques are extensively used in rapid prototyping, providing cost-effective solutions for design verification and validation.

Key points about the application of low-volume prototyping in rapid prototyping include:

- Rapid prototyping services leveraging low-volume manufacturing processes allow for quick turnaround times, enabling design changes and validation within shorter time frames.

- Low-volume prototyping provides the means to produce high-quality prototype parts, ensuring an accurate representation of the final product.

- It allows for the testing of different factors, such as production processes, surface finish, and tight tolerances, enhancing the development process.

- Rapid prototyping services offer a comprehensive guide for new product development, facilitating design adjustments and optimization.

Relevance in Short-Run Production

Low-volume prototyping plays a significant role in short-run production, where limited quantities of parts need to be produced quickly and efficiently. Short-run production often requires high strength, customization, and quick turnaround times, making low-volume manufacturing methods the best option.

Key points about the relevance of low-volume prototyping in short-run production include:

- Low-volume prototyping techniques enable quick turnaround of prototype parts, facilitating design verification and validation in the production process.

- It allows for the validation of design changes before committing to mass production, reducing the risk of costly mistakes.

- Low-volume production methods provide the flexibility to produce smaller batches of parts, meeting the demand for limited quantities without compromising on quality or strength.

- Low-volume manufacturing has revolutionized short-run production, offering cost-effective solutions, high-strength prototype parts, and shorter lead times.

Strategies for Effective Low-Volume Prototyping

To ensure the successful implementation of low-volume prototyping, companies need to adopt effective strategies that optimize the process. Adaptive lean prototyping and just-in-time prototyping are two such strategies that have proven to be beneficial. Let’s explore these strategies to understand how they enhance the efficiency of low-volume prototyping.

Implementing Adaptive Lean Prototyping

Adaptive lean prototyping is an approach that focuses on rapid response and quick design changes, involving the collaboration of product designers, engineers, and other stakeholders. It enables efficient low-volume prototyping by allowing design changes to be made on the go, leading to shorter lead times and faster development cycles.

Key points about implementing adaptive lean prototyping include:

- Product designers adopt a collaborative approach, working closely with the manufacturing team to make real-time design changes and enhancements.

- Adaptive lean prototyping ensures shorter lead times, allowing for quick validation of design changes and adjustments.

- The expertise of the design team plays a crucial role in ensuring high-quality prototype parts that meet the desired specifications.

- The method caters to the complexity of the part, customization, and personalization requirements of the product, leading to the development of high-quality parts.

Benefits of Just-in-Time Prototyping

Just-in-time prototyping is a method that aims to reduce lead times by manufacturing parts only when they are needed, eliminating the need for extensive inventory management. It offers several benefits in low-volume prototyping, optimizing production processes, and reducing costs.

Key points about the benefits of just-in-time prototyping include:

- Just-in-time prototyping ensures shorter lead times, as parts are produced on demand, reducing the waiting time between design changes and validation.

- It results in cost savings, as manufacturers do not have to maintain large inventories, reducing the production costs associated with excess material storage.

- The method optimizes production processes, streamlining the manufacturing flow, and improving overall efficiency.

- Just-in-time prototyping enables rapid-scale production, allowing companies to respond quickly to changes in demand and market trends.

Case Studies: Low-Volume Prototyping in Action

To understand the real-life applications and benefits of low-volume prototyping, let’s explore a few case studies where the process has been successfully implemented in different industries.

Overcoming Challenges in Low-Volume Prototyping

While low-volume prototyping offers numerous benefits, it also comes with its own set of challenges that need to be overcome. Let’s discuss some common challenges faced in low-volume prototyping and the strategies to address them.

How Has Low-Volume Prototyping Revolutionized Industries?

The advent of low-volume prototyping has revolutionized industries by offering cost-effective solutions, high-quality prototype parts, and shorter lead times. Let’s explore how this manufacturing process has transformed different sectors.

Conclusion

In conclusion, low-volume prototyping plays a crucial role in various industries, enabling rapid innovation and efficient production. By bridging the gap between prototyping and mass production, it allows for cost-effective testing and validation of designs before full-scale manufacturing. Whether it’s in pilot projects or limited production runs, low-volume prototyping offers flexibility and agility to meet market demands. Techniques like CNC machining and additive manufacturing/3D printing have revolutionized the prototyping process, making it faster and more accessible. With its wide range of industrial applications, from rapid prototyping to short-run production, low-volume prototyping has become a game-changer for businesses looking to stay competitive in today’s dynamic market. To explore how low-volume prototyping can benefit your industry, get in touch with our experts today.